|

Dispatching system of the poultry-yard

Founded: November 2010 |

|

Contents

Now "Yaroslavsky Broiler" is the only specialized enterprise in production and processing of meat of broiler chickens in the Yaroslavl region. Today in the company there is a closed production cycle: from the production of hatching eggs to the finished product. A distinctive feature of the factory is its own network of company stores and its own fleet of vehicles and the availability of wholesale warehouses make possible the quickly delivering of meat products to the consumer, including central and remote regions of Russia.

More modern poultry farms select for factory automation poultry breeding equipment firm "Big Dutchman", represented by specialized modular computers microclimate and control "Viper", among them "Yaroslavsky Broiler". Poultry farm has about 20 chicken houses with about 5 rooms in each.

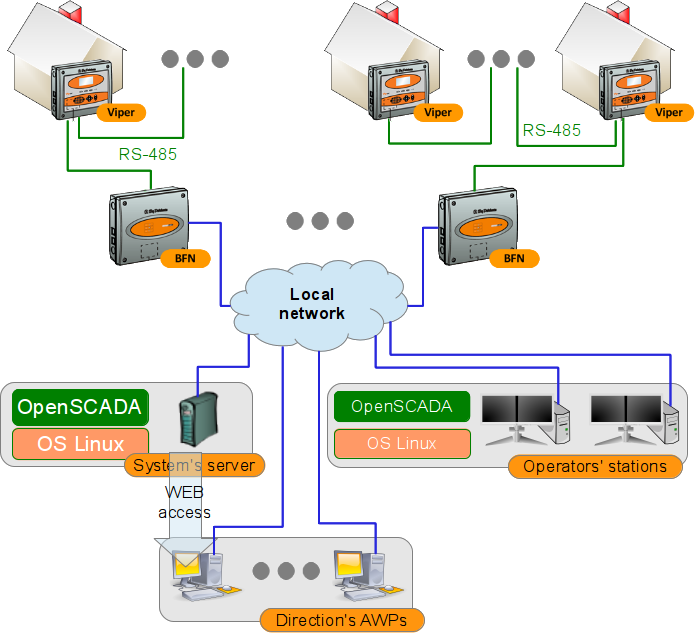

Typical configuration with using "Viper" is setting one computer in each room, which next grouping by aviaries. For central supervisory control over the technological process and operative responding the computers connecting to poultry farm network forming modules BFN(BigFarmNet), from which, in turn, data represents into program "Infomatic" by firm "Big Dutchman".

However, the decision of the company for the operational process monitoring ("Infomatic") has the set of limitations on productivity, which is further exacerbated by a large number of specialized computers and large amounts of data from one computer (200-500 signals). Since data from the room computers are concentrated in one BFN(BigFarmNet) module, and then are acquired by the dispatching program. The specialized software for the modules' acquisition makes the acquisition of the BFN module of one chicken house within five minutes, and can not make a parallel inquiry of the BFN modules of separate chicken houses, that in total is approximately 1.5 hours to update data for all twenty poultries. Naturally, this can not be called the operational control and the factory decided to solve the problem.

1 OpenSCADA

To solve this problem, it was decided to implement optimized and compact inquiry of the BFN modules' data of the chicken house in the amount of the current values of signals and alarms in parallel mode. Since OpenSCADA has developed mechanisms for data acquisition, storage and presentation, as well as it is an open system, it was decided to write the BFN acquisition module for it.

As a result of the work it was written the module of the BFN inquiry, which allows you to acquire all the controllers' data, which are connected to the BFN of the chicken house with alarms for each. In general, the amount of obtained data from one chicken house (6 rooms) is 1500 signals with an average time of inquiry 12 seconds. As the inquiry of an individual chicken house (BFN module) is made regardless, the total time of the inquiry of twenty chicken houses will be those same 12 seconds. Archives of signals, as required, are included and stored in OpenSCADA with optimization on access time and size that allows you to fully control the history of the process.

Acquisition and visualization of data of the poultry are implemented on the dedicated server, the dispatcher's station and the direction's workplaces:

- The dedicated server is implemented on an office PC with Intel Atom D520. On the server the inquiry and data archiving of the chicken houses (BFN modules) are running.

- The dispatcher's station is implemented on an office PC with Intel Atom D520 and is used for operational control of the process through the data obtained by the dedicated server.

- On the direction's workplaces the Web-based interface through the dedicated server is provided to assess the current state of the process and its history.

Visualization interface is represented by several signal objects with the following composition:

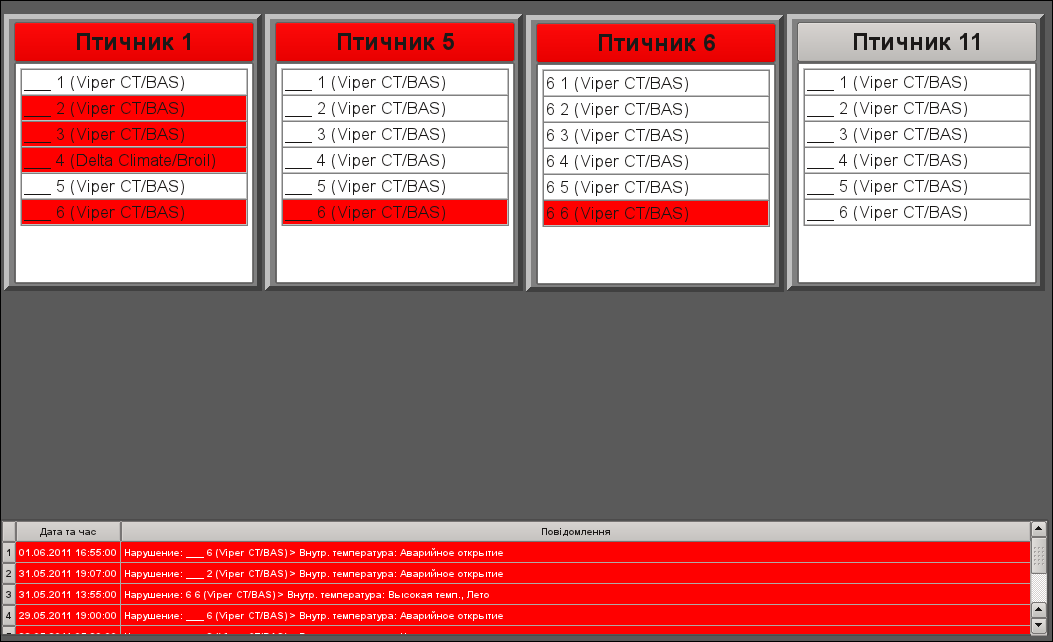

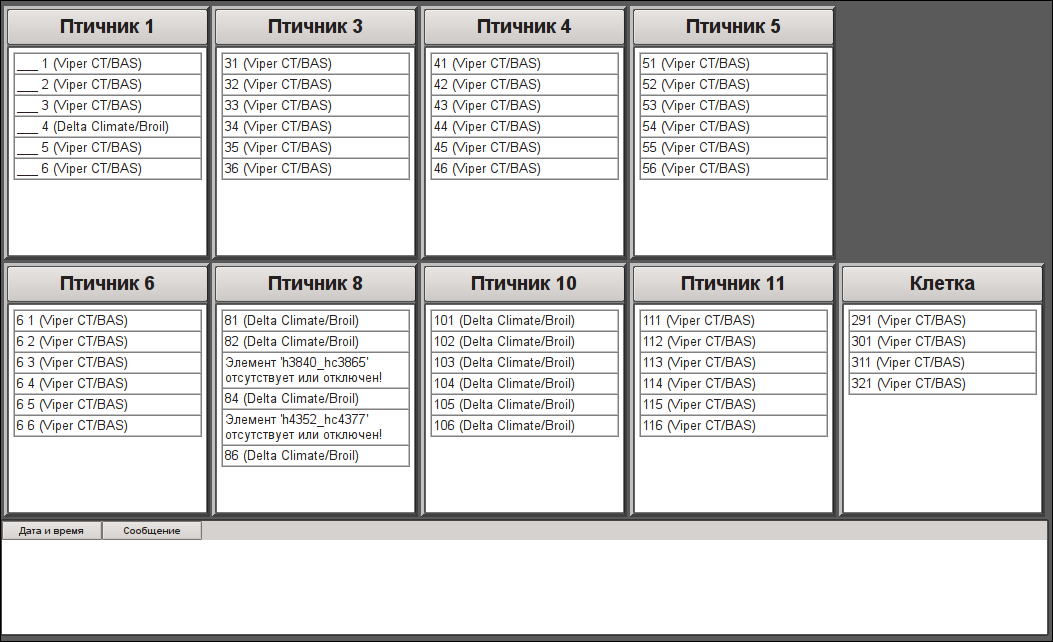

- "General": The main mnemonic scheme of the poultry contains the chicken house blocks with the set of the rooms and their alarms.

- "Aviary {N}": The chicken house mnemonic scheme with the table of the selected signals and their alarms; alarms report of the chicken house with their history.

There is the possibility of expanding the visualization interface by adding a new chicken houses to the signal objects and to the main mnemonic scheme by copying the present chicken house. The resulting information poultry farm structure is shown in Figure 1.

2 Functions

The supervisory system based on OpenSCADA can be implemented on single operator station, combining acquisition server's functions, and also distributed, ie server separated, and stations visualization-operator also separated in the right quantity. And visualization can be doing on special for that task specified computers, through reliable and productive interface which based on library Qt4, and also on computers administrative and engineering personals as a Web-based interface.

The operative control interface for poultry farm based on OpenSCADA allow several frames:

- "Summary information frame"

- "Same aviary frame"

- "Violations protocol"

Beside for counted frames we can create other need frames, for example: overview trends frame for selected data by aviary with history storage on server to long deep, mnemonic schemes with structural displaying different signals by aviaries rooms and etc.

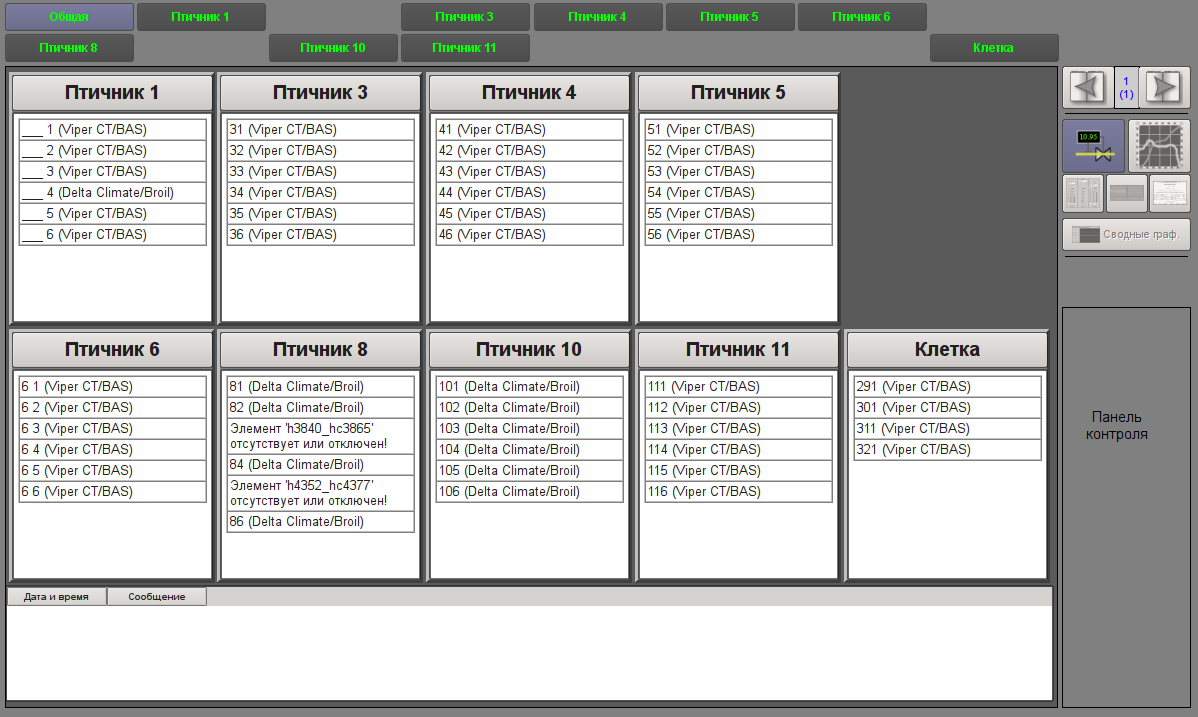

Main operator interface is presented on Figure 2.

Top of the main interface presented buttons for the signal object select with the main frame and different aviaries. At presence a violation respectively to aviary will highlighted signal object button, which allow for operator go to the aviary with the problem and rapid localize it.

Top right shown list buttons between frames into single signal object. Under the list buttons placed views shown buttons, where operator can select mnemonic schemes, graphics, documents and etc. Under the views shown buttons placed control panels area, where can display control panels by parameters, graphics, documents and etc, depends from selected control context.

Into central of the main interface placed the frames display area which variations are displayed bottom.

2.1 Summary information frame

The frame, in individual aviaries blocks, contained violations stats for every room into the aviary and general violation by aviary (Fig.3). Clicking to the aviary stat button you can go to the frame with violation details and with data by individual aviary. Bottom to the summary information frame placed the table with a general list of violations by plantry farm. According to the image bellow there is violations into rooms 2-4, 6 into aviary 1.

Figure 4 shows main signal object frame of "Yaroslavsky Broiler" poultry at this time where are no violations present.

2.2 Aviary data frame

The aviary frame contains the table with selected data values by rooms and the table generic list of violations by the aviary (Fig.5). Also on the frame placed button for violations clear, it sometimes takes by protocol with BFN feature.

During localization the problem, which we have start into previous chapter by have switch to the signal object aviary 1, operator will take exactly the frame from which he will see that the problem into rooms 2-4, 6 aviary 1 have violation "Internal temperature". Into table bottom you can get information about violations for all parameters and not just those selected by operator for observing to the current values into main table on top.

2.3 Violations protocol

To provide the possibility study violations history of each aviary provided frame of violations protocol (Fig.6), which contains the violations table for specified period of time.

Control for the violations protocol display performed by the control panel, which appear into the control panels area right when the mouse on the document press. The resulting document you can export and print.

3 Conclusion

With OpenSCADA project's help you can build systems for acquisition, supervision and control to different complexity and due to the open nature possible adaptation to initially not conductive environment and often achieve more quality features. Due to this poultry farm supervisory control realization base on OpenSCADA allow you to reach operational control level with large data volumes, and also improve the overall quality of production through timely response to violations.